High-Speed Fill-Seal Machines

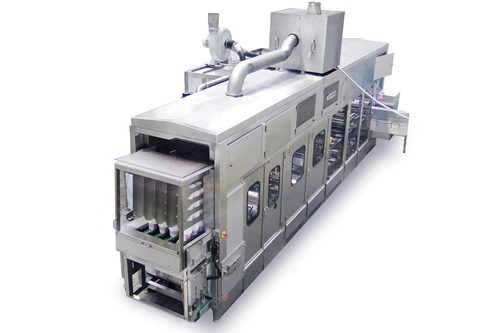

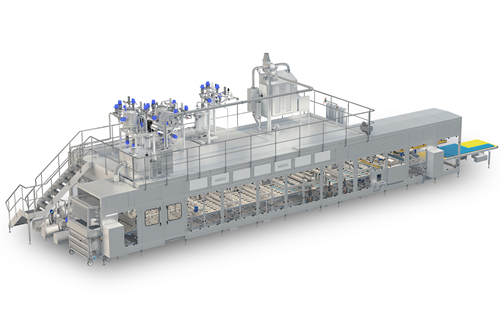

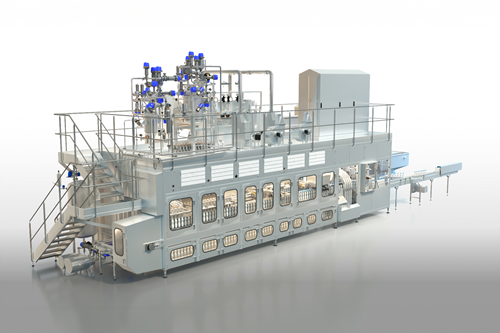

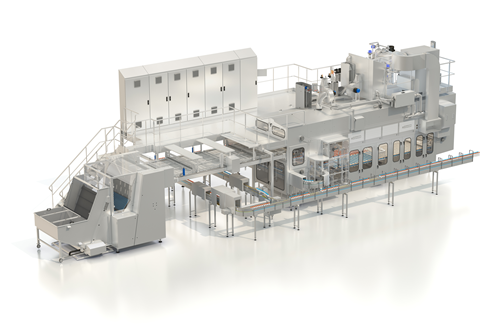

The versatile Fill-Seal (FS) machines by DAIRY PACK are designed to handle various cup and bottle shapes and materials, from plastic to glass, and cater to both small and large production runs. With Speed up to 60,000 containers per hour, DAIRY PACK ensures efficiency, flexibility, and high cost-effectiveness for all your packaging needs. These machines can fill and seal preformed cups or bottles, and easily integrate with cappers, end-of-line, and other equipment for a seamless production process.

Browse all our DAIRY PACK FS machine below.

About High-Speed Fill-Seal Machines

How do Fill-Seal machine work?

In brief, Fill-Seal (FS) machines, whether they handle and fill bottles, trays or cups, receive empty pre-formed containers, which are subsequently filled with the product and thermosealed with a roll or film to guarantee the freshness of the product. After which, the filled and sealed container will be ejected through a conveyer to the end-of-line machines to pack and/or palletize the product before having it shipped to the customer.

Often, Fill-Seal machines will also include a module for container decontamination to ensure that the preformed container is ready to be filled and closed.

FS portfolio, technical data

Cups Fill-Seal portfolio

| Hygiene | Containers | Materials | Sizes | Options | Filling Volumes | Units/stroke | Units/Hour | |

|---|---|---|---|---|---|---|---|---|

| DAIRY PACK DP40C | Ultra-clean | Cups | Paper, Plastic, Alum | 55 - 95 mm cup ø | 1 cup ø | 90-500 ml | 1x2 to 2x6 | 5,000 to 18,000 |

| Ultra-clean | Buckets | PS, PP, PET | 150 - 270 mm bucket ø | 1 bucket ø | 1,000-2,500 ml | 1x1 to 1x3 | 1,500 to 4,100 | |

| DAIRY PACK RM90C | Ultra-clean | Cups | Paper, Plastic, Alum, Glass | 60 - 160 mm cup ø | Up to 3 cups ø | 80-1,500 ml | 1x2 to 2x12 | 12,000 to 30,000 |

| DAIRY PACK RM12C | Ultra-clean | Cups | Paper, Plastic, Alum, Glass | 60 - 160 mm cup ø | Up to 3 cups ø | 80-1,500 ml | 1x2 to 2x16 | 24,000 to 60,000 |

| DAIRY PACK DN60R | Ultra-clean | Cups | Paper, Plastic, Alum | 65 - 120 mm cup ø | 1 cup ø | 90-500 ml | 1x3 | 4,000 to 5,000 |

Bottles Fill-Seal portfolio

| Containers | Materials | Sizes | Options | Filling Volumes | Units/stroke | Units/Hour | |

|---|---|---|---|---|---|---|---|

| DAIRY PACK RM40B | Bottles | PET, HDPE, PP, PS | 40 to 88 mm body ø | 1 or 2 neck diam | 80-1,500 ml | 1x4, 1x5 or 1x6 | up to 12,000 |

| DAIRY PACK RM80B | Bottles | PET, HDPE, PP, PS | 40 to 88 mm body ø | 1 or 2 neck diam | 80-1,500 ml | 2x4, 2x5 or 2x6 | up to 24,000 |

| DAIRY PACK RM12B | Bottles | PET, HDPE, PP, PS | 40 to 92 mm body ø | 1 or 2 neck diam | 80-1,000 ml | 1x12 | up to 24,000 |

| DAIRY PACK RM15B | Bottles | PET, HDPE, PP, PS | 40 to 92 mmbody ø | 1 or 2 neck diam | 80-1,000 ml | 1x15, 1x24 or 1x30 | up to54,000 |

Form-Fill-Seal vs Fill-Seal machines

Food and beverage producers often ask whether they should buy a Form-Fill-Seal machine or a Fill-Seal and to answer this question, we should take into account at least 8 aspects: Production Volumes, Operational Requirements, Sustainability needs, Shelf-Appeal needs, Container Quality, Hygiene Requirements, Pack Formats and Capital Expenses.

Our knowledge owner expert has compiled a list with explanation of how to choose between an FFS and an FS machine for your dairy packaging, read the blog post.