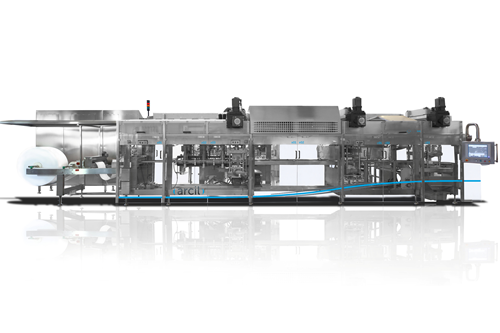

Efficient Form-Fill-Seal Machines

The Thermoform-Fill-Seal (FFS) machines by ARCIL are designed for low, medium and high-speed productions and flexible packaging solutions. Ideal for (r)PS, (r)PET, PLA, and PP cup packaging, these machines ensure consistent product portions and freshness. With over 400 machines globally, ARCIL offers customizable options to meet your production needs, enhancing efficiency and reducing material losses, while optimizing operator ergonomy. Optimize your packaging and your Operational Expenses with ARCIL advanced technology.

Browse all our ARCIL FFS machines below.

Inline Form-Fill-Seal machines with speeds up to 60,000 cups per hour and 120,000 cups per hour, with customized lavel design possibilities: L-Paper label, J-Paper label, U-Paper label, Thick Paper label, Plastic OPS label, Plastic PET label and Conical label.

About Efficient Form-Fill-Seal Machines

How do Thermoform-Fill-Seal machines work?

In brief, Form-Fill-Seal (FFS) machines use heat and air pressure to convert various plastics into a container, may it be a cup, a tray or a mini-portion.

In particular, Thermoform-Fill-Seal machines convert a sheet of plastic into containers through the process called thermoforming, these containers are subsequently filled and thermosealed with a roll or film to guarantee the freshness of the product. After which, the containers go through one last step, the separation of the containers from one another to form single portions or multi-packs.

Form-Fill-Seal vs Fill-Seal machines

Food and beverage producers often ask whether they should buy a Form-Fill-Seal machine or a Fill-Seal and to answer this question, we should take into account at least 8 aspects: Production Volumes, Operational Requirements, Sustainability needs, Shelf-Appeal needs, Container Quality, Hygiene Requirements, Pack Formats and Capital Expenses.

Our knowledge owner expert has compiled a list with explanation of how to choose between an FFS and an FS machine for your dairy packaging, read the blog post.

FFS portfolio, technical data

| Material | Cup shape and label | Filling Volume | Cups/hour for 100ml cup | |

|---|---|---|---|---|

| ARCIL DN200 | PS, PP, Multilayer | Mini Portion, 360° straight, conical | 10-240 ml | 1,440 to 5,400 (10,800 for mini-portions) |

| ARCIL DN250 | PS, PP, PET, Multilayer | Mini Portion, 360° straight, conical, straight label | 10 - 100 ml | 14,400 to 21,600 (36,200 for mini-portions) |

| ARCIL DN450 | PS, PP, PET, Multilayer | Mini Portion, no decor | 10 - 240 ml | Up to 31,600 (42,240 for mini-portions) |

| ARCIL DP100 | PS, PET, PLA, PP, Multilayer | Mini Portion, Paper Label, Straight, Full or Partial height | 10 - 1,000 ml | Up to 7,200 ( 21,600 for mini-portions) |

| ARCIL DP300 | PS, PET, PLA, PP, Multilayer | 360° straight, conical, wave decor label, partial IML, capping | 25 - 1,000 ml | 14,400 to 28,800 |

| ARCIL AR700 | PS, PET, PLA, PP, Multilayer | 360° straight, conical, wave decor label, partial IML and open-mold | 25 - 1,000 ml | 26,880 to 57,600 |