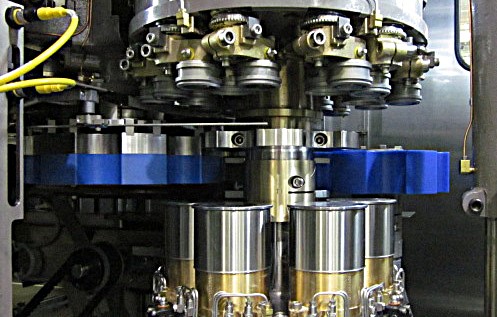

Continental Can Seamers

The CONTINENTAL name has long been synonymous with excellence in can seaming and since 1995 it has been part of the Barry-Wehmiller family through a series of acquistions that brought us Continental's Closetech line of seamers. Today, we continue to provide sales, service, and support for these machines, as well as offering pre-owned and rebuilt models. This line includes 4 seamer families designed to address the needs of Food and Beverage producers with models designed to accommodate projects of differing speeds, can sizes, and even agitation. The four lines include the Rotary Closing Machine (RCM), the High-Speed Closing Machine (HCM), the Rotary Double Seamer (RDS), and the High-Speed Double Seamer (HDS). Although very different machines, they share some common attributes:

- Careful, expert engineering that designs efficiency and lower costs into machines

- Easy operation and maintenance

- Reduced downtimes and fast changeovers

Parts & Service

OEM parts and experienced Customer Service are key to maintaining the integrity and service of your equipment. We offer spare and replacement parts for all of our product lines, as well as a dedicated team of professionals who provide global support, delivered locally. If you need support, contact our team and a dedicated support professional will respond to your request.

-

10 Ascot Pkwy

Cuyahoga Falls OH 44223

US -

+1 (800) 992-0491

Training

Products, Markets and Speeds for CONTINENTAL

The CONTINENTAL portfolio is known for its reliability and robustness in various markets, which encompasses both food and beverages.

With speeds that range from 300 to 1200 cans per minute, these seaming machines allow for cans of different diameters, from 2 to 7-1/16" (50.8 - 179.37mm), and heights from 1-5/8 to 9-5/8" (41.28 - 244.48 mm).

CONTINENTAL and its History of Innovation

Started in 1910, CONTINENTAL is another BW Packaging brand with over a century of innovation and success behind it.

Continental machines have been designed with the versatility to accommodate a wide range of products and can sizes, yet still allow for height changeovers in just minutes. This quick-change feature is achieved through a concept that supports and drives all height change-related components directly from the top housing. The simplicity of the design ensures ease of operation and maintenance, catering to the varying skill levels of personnel employes worldwide. These seamers have been value-engineered to meet the current and future needs of the can-making industry, with a high degree of parts interchangeability.

As with all of our machines, the Continental line is supported by superior customer service, OEM changeparts, and expert engineering and field service.