.png?sfvrsn=1a5f555f_0&MaxWidth=800&MaxHeight=700&ScaleUp=false&Quality=High&Method=ResizeFitToAreaArguments&Signature=1D60232FF9866D5AF2AF5772E0E55BC9BA9EA6EB)

Synerlink is Now BW Filling & Closing

Synerlink and Pneumatic Scale Angelus joined forces to become BW Filling & Closing. Its portfolio integrated the brand you love and trust ARCIL, DAIRY PACK and HEMA with some of the industry-leading packaging brands like ANGELUS, BURT, CONTINENTAL, MATEER, PNEUMATIC SCALE and ZEPF SOLUTIONS.

BW FILLING & CLOSING AT A GLANCE

1,000 Team Members

Presence in 5 Continents and 16 Countries

20,000+ Installations Worldwide

New Equipment & Aftermarket

Packaging Equipment

Long Term Partnerships

Synerlink Brands

Together with Pneumatic Scale Angelus Brands

Angelus

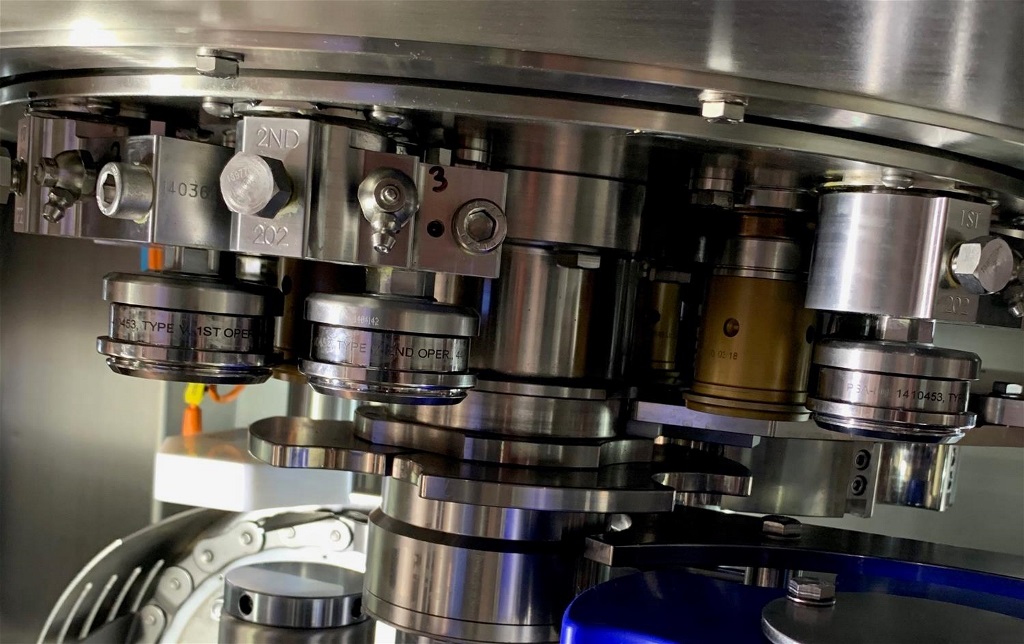

BW Filling & Closing's ANGELUS brand is recognized as a global leader in can seaming technology, providing high-performance machines that set the standard for seam integrity in the Food and Beverage industries.

More than a century ago, Angelus pioneered the use of the double seam, a hermetic seal formed by mechanically interlocking three layers of metal from the can end with two layers from the can body. This innovation transformed the canning industry by creating an airtight seal that ensured the preservation of the contents within the can and its safety for human consumption, as well as extending shelf stability. The development was so revolutionary, it became the inspiration for the Angelus logo still seen on our products today.

Today's modern Angelus continues this legacy of innovation, serving nearly every industry, in applications as varied as canned vegetables to meats, craft beverage to high-speed soft drinks, and oil filters to caulk tubes. Known for hygienic design, fast and reliable changeover, and superior lightweight can handling, and backed by world-class service and support, Angelus is the brand you can trust.

Angelus can seamers are recognized as the industry standard for quality and reliability for Food and Beverage producers.

- ANGELUS V-Series - Model 3V

- ANGELUS V-Series - Model 4V

- ANGELUS V-Series - Model 6V

- ANGELUS V-Series - Model 8V

- ANGELUS V-Series - Model 9V

- ANGELUS V-Series - Model 12V

- ANGELUS V-Series - Model 18V

- ANGELUS Legacy Series - Model 60L

- ANGELUS Legacy Series - Models 61H / 62H / 63H

- ANGELUS Legacy Series - Models 100L / 101L

- ANGELUS Legacy Series - Models 120L / 121L

- ANGELUS Legacy Series - Model 181S

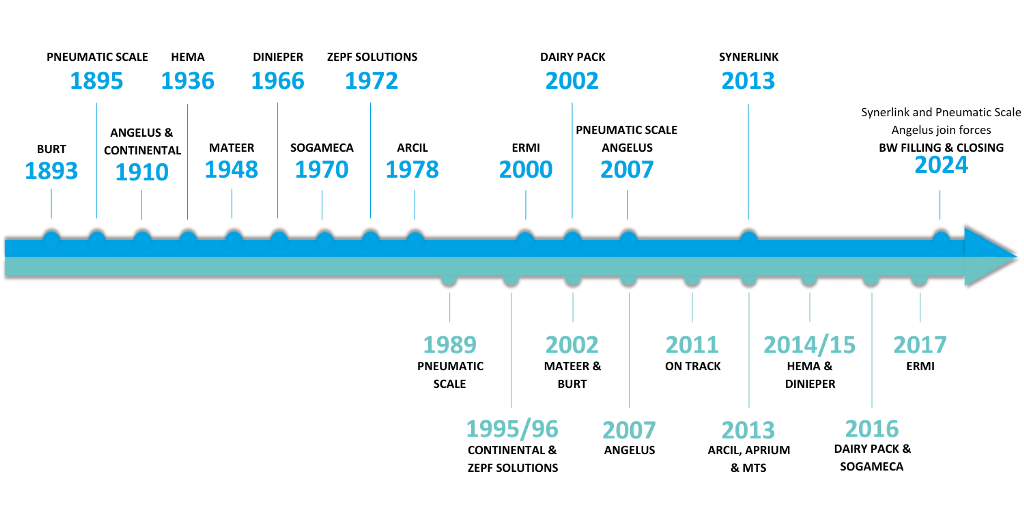

Synerlink history

Hema was first established in 1936 in Quimper, Brittany, France. The company developed the first rotary piston filler for sauces and jam in 1939 and evolved to produce rotary and linear fillers for liquid, viscous, and semi-solid products like oil, dairy, dressings, meat and fish. In 2008, Hema developed the first Combi machine for yogurt, showcasing their innovative approach to filling technology.

Arcil was founded in 1978, and was subsequently acquired by Danone, a world-leading food producer, in 1992. In 1994, Arcil introduced a new generation of Thermoform-Fill-Seal (FFS) machines. The company was later renamed Synerlink in 2009, when it began creating complete lines for dairy products. Barry-Wehmiller acquired Synerlink in 2013, further expanding its capabilities in the packaging industry.

In 2015, Barry-Wehmiller acquired Hema, and in 2016, it acquired Ermi and Sogameca, which became part of Synerlink, while Hema and Synerlink officially joined forces only in 2022, combining their expertise to provide comprehensive solutions for the food and beverage industry. This strategic collaboration has strengthened their position as leaders in packaging technology.

The Creation of BW Filling & Closing

Both companies were operating under the umbrella of Barry-Wehmiller as separate entities, until 2024 when Pneumatic Scale Angelus and Synerlink joined forces to become BW Filling & Closing. Since then, BW Filling & Closing has been working on enhancing customer services globally, and creating innovative, best-of-line equipment for our clients.

Serving You Worldwide

A Global Team for Local Support

Our footprint around the world is designed to close to your production sites. Speak with the representative closest to you and your team, and enjoy a network of more than a thousand packaging experts to help you every step of the way.